Description

Product Brochure

PRC® aerospace sealants were the first products capable of resisting deterioration from long-term exposure to jet fuel. Since then, sealants such as PR-1422 and Pro-Seal™ 890 have become acknowledged industry standards for sealing fuel tanks.

This tradition of leadership continues with innovative new sealants based on our advanced Permapol® polymers. These sealants are lighter in weight, withstand higher temperatures, cure faster, and are easier to apply.

Supported by a global network of Application Support Centers, each staffed by technical support specialists who can quickly provide needed service and information, PPG Aerospace – PRC-DeSoto continues to establish higher standards for products and service excellence.

We’re at work in a variety of aerospace sealant applications:

-

- Improve quality, reduce application time, and reduce waste

- Environmentally friendly, light weight / low density, rapid cure materials

- Customized Sealant Solutions (CSS) – sealing solutions in preformed shapes designed to simplify the sealing process: Seal caps and Semfoam™ Sealants

- Durable, quality performance Aerospace Sealants

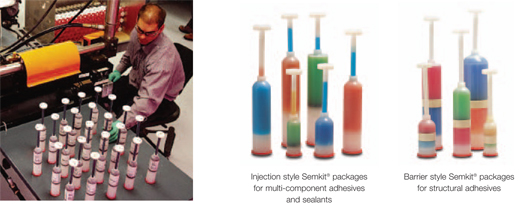

- Convenient and efficient containers including Semkit® packages and PRC® Pre-mixed and frozen (PMF) cartridges

- Fuel resistant Industrial Sealants and Adhesives products created with PPG Aerospace technology

- Adhesion Promoters

- An Adhesion promoter will enhance the coupling characteristic of our sealants to a wide variety of substrates.

Application Guides

Sealant Application Guides

Corrosion Inhibitive Sealants

Corrosion Inhibitive sealants will act as an effective barrier against the common causes of corrosion on aluminum alloys or between dissimilar metals.

Customized Sealant Solutions (CSS)

A family of products designed to simplify the sealing process.

Electrical Potting / Molding

PRC polyurethane potting and molding materials are designed for potting electrical connectors and/or molding electrical cable assemblies. These polyurethane compounds are suitable where high dielectric, high abrasion, flexibility, high tensile strength, and excellent hydrolytic stability are required.

Electrically Conductive

These cured sealants maintain electrical continuity in aircraft applications.

Fast Cure / Flight Line Repair

These sealants are rapid cure, aircraft integral fuel tank and fuselage sealant. The cured sealant maintains excellent elastomeric properties after prolonged exposure to both jet fuel and aviation gas.

Fuel Tank / High Performance Options

Expanding the performance envelope in areas such as higher strength, temperature range and weight reduction.

Fuel Tank / Proven Standards

The cured sealant maintains excellent elastomeric properties after prolonged exposure to both jet fuel and aviation gas. It cures at room temperature to form a resilient sealant having excellent adhesion to common aircraft substrates.

High Temperature and Firewall

The material is designed for sealing firewall structures against the passage of air and vapors.

Specialty Products

A variety of specialty sealants offered by PRC DeSoto.

Windshield and Canopy

The cured sealant exhibits excellent resistance to UV and weather exposure. These products are specifically formulated not to craze substrate.

Industrial Sealants and Adhesives

High performance sealants to provide protection from fuel and petroleum exposure Sealants for Telecom and Utility applications