Description

Powerful intelligence, by touch or voice

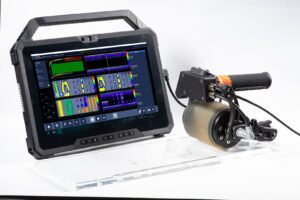

Driven by advanced analytics to inspect in entirely new ways, the more intelligent MVIQ+ leverages computer vision and machine learning to increase data quality while reducing inspection times. The new voice command feature lets inspectors perform measurement, data sharing, and more without needing to touch the MViQ+ directly.

The Everest Mentor Visual iQ+ is the only video borescope that features voice-activated commands, making it possible to freeze-frame live video, increase dark boost, save an image, and more — without the need for an extra hand. So go ahead: your wish is our command.

| HD Resolution and 3D Image Stitching |

HD Resolution and 3D Image StitchingThis industrial borescope offers on-demand measurement with the most advanced 3D capabilities, providing more accurate measurement from increased distances. 3D Stitching combines individual images and corresponding point clouds to a larger image which enables measurement of larger defects across multiple images and the ability to accurately locate the position of defects in relation to a fixed point-of-interest. Users can adjust cursor placements in the fully-surfaced Point Cloud to deliver results with confidence. What’s New with 3D Stitching

|

| Real3D™ Measurement – Advanced 3D Inspection Software |

Advanced 3D Inspection SoftwareReal3D™ measurement combines fully surfaced point cloud visualization, advanced measurement algorithms and an insightful 3D Surface Mask to enable more accurate and repeatable measurement decisions. Choose from Real3D Stereo or 3D Phased Measurement which allows measurement on-demand without changing tips. Each of these technologies is compatible with some or all measurement types to help get the measurement needed in every application. They include basics like length, depth point to line and area, but also specialty types including missing corner area, area depth profile, automatic tip blade clearance and radius gauge for boro-blending assessment. Aside from measurement types, Real3D provides advanced tools such as depth assist and measurement plane to further increase accuracy of measurements. What’s New with Measurement?

|

| Defect Detection & Blade Counting |

Defect Detection and Blade CountingLeverage computer vision and machine learning to help improve consistency and reliability of inspection tasks and increase the overall quality of an inspection output. The Mentor Visual iQ+ enables users to leverage analytical models from multiple sources.

What’s NewAnalytic models updated with additional training images to improve performance

|

| TrueSight™ Image Software |

TrueSight™ Image SoftwareTrueSight™ provides a blend of high resolution image capturing and processing functions, precision optics and a powerful suite of proprietary image transforms used to enable better visual inspection decisions. The suite of image transforms is included in the Pro package and available for Start and Enhance. This POD SW includes the following (click to watch videos): Adaptive Noise Reduction (ANR), Dark Boost, Distortion Correction, Inverse+, Variable High Dynamic Range (VHDR) and Color Saturation. |

| Cloud Connectivity and InspectionWorks |

Cloud Connectivity and InspectionWorksThe MVIQ+ comes with InspectionWorks, a secure and scalable cloud-based inspection platform that integrates every component of the nondestructive testing , turning data into useful intelligence for faster and better decisions.

|

| Turning Tool Integration |

2-Way CommunicationTo enable repeatable image capture of every blade in each stage, the updated protocols let the MViQ+ video borescope and the Rhinestahl FutureDrive NG+ turning tool perform 2-way communication. Previous time delay image capture can sometimes cause errors and consume unnecessary waiting time between stop and image capture. Now consistent images are provided in less time. |

Customize Your MViQ+ Package

Customers can choose between 3 MViQ+ base packages to determine which Mentor Visual iQ+ features are right for them.

MViQ+ START |

MViQ+ ENHANCE |

MViQ+ PRO |

| Touch Screen

40GB User Storage Menu Directed Inspection Comparison Measurement InspectionWorks Far Field Audio 90-Day Analytics Trial Free Software Updates |

START, plus:

Interchangeable Probes 80GB User Storage HD Imaging Turning Tool 2.0 1-Year Analytics (Blade Counter, GasPower assist) |

START and ENHANCE, plus:

160GB User Storage 2-Year Analytics (Blade Counter, GasPower assist) All Probability of Detection Measurement Bundle options |