Description

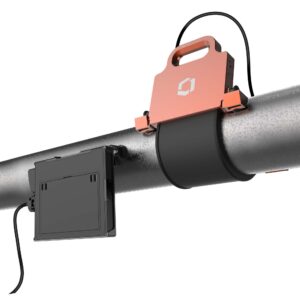

CleanTech Industrial Conditioning Laser 2010

The CleanTech Industrial Conditioning Laser 2010 is a versatile handheld dual-axis pulsed laser system designed for both finishing and coarsening applications in-field and at warehouses. This compact device offers higher throughput and substrate alteration capabilities compared to less powerful finishing lasers.

Engineered for user-friendly operation and durability, the CTIC-2010 requires no consumables for surface treatment tasks. This next-generation system features mobile connectivity, overheat protection for enhanced safety, and a smaller scanhead for improved portability and ease of use.

Applications for CTCF-1020

| Surface Conditioning | Degreasing |

| Corrosion Removal | Surface Preparation |

| Decontamination | Surface Texturing |

| Coating Removal | Injection Mold Cleaning |

| Pre-Adhesion Treatment | Oxide Removal |

| Pre-Weld Preparation | Anodization Removal |

| Post-Weld Treatment |

Materials That the CTCF-1010 Can Be Used With

| Aluminum | Composites |

| CFRP | Nickel |

| Steel | Concrete |

| Silicone | Chrome |

| Copper | Ceramics |

| Plastics | Cast Iron |

| Brass | Marble |

| Thermoplastics | Carbide |

| Titanium | & More |

Technical Specifications for CTCF-1010

| Model | CTIC-2010 |

|---|---|

| Strip Rate Per Hour | 36 ft² |

| Laser Type | Fiber |

| Scanner | Dual Axis |

| Operation Mode | Pulsed |

| Wavelength | 1064 nm |

| Laser Pattern | 5 Presets |

| Head Cable Length | 9.8 – 30 ft (3 – 9 m) |

| Head Weight | 3.5 lbs |

| Size W x H x D | 22 x 44 x 18 in (559 x 1118 x 457 mm) |

| Unit Weight | 150.5 lbs |

| Temperature | 41 – 104 °F (5 – 40 °C) |

| Humidity | 10 – 90 % Non-Condensing |

| Operational Voltage | 220V | 50 – 60Hz | 15A |

| Cooling | Air |

| Safety Class | IV |

| Safety Features | Emergency Stop Button | Key Control | Remote Interlock Connection | Emission Indicator | Air Pressure Sensor | Overheat Protection |

| Mobile Connectivity | Yes |