Description

If you’re trying to prevent grade mix-ups of incoming and outgoing materials, conduct material verification and quality control, or maximize profits in a scrapyard then we’ve got the solution for you. With the PMI-MASTER Pro2, you’ll have confidence that you’re getting the analytical performance you need to make the right decisions.

Reliable carbon analysis

Accurate carbon analysis from L grade stainless steels to low alloy and carbon steels. You can measure carbon and boron with any of our spark probes. With a UVTOUCH probe, you can

measure phosphorous, sulfur and boron as well as nitrogen in duplex steels.

This is why spark OES is the most trusted and widely used method for creation and verification of MTRs (mill testing reports) in the world. Our optical emission spectrometers also meet the world most stringent PMI metallurgical alloy chemistry testing requirements including API 5L, ASME section IX B&PV, ISO 17025 and A2LA standards

Why choose the PMI-MASTER Pro2?

Reliable C analysis

Accurate carbon analysis from L grade stainless steels to low alloy and carbon steels.

Ready to go

Short warm-up time means you’re up and running in no time.

Low argon consumption

Concentric electrode shielding argon flow technology reduces air gaps and optimizes gas flow.

Universal adaptors

Rubber seal for concave and convex surfaces allows analysis of almost any sample.

Technical specifications

Multi-CCD optics in Paschen-Runge mounting and optimised pixel resolution

Lead gel battery: SPARK measurements up to 120/759 and ARC measurements to up 80/500 (using standard parameters)

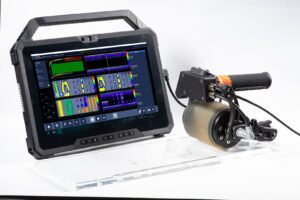

Computer system: Internal computer unit and touch screen user interface

2-year extended warranty as standard*.

Typical applications

- Steel alloys

- L grade segregation in stainless steel

- N*, C, P*, S*, Sn*, As*, B* analysis in steel

- Al alloys ~ Al-Si ~ Al-Si-Cu

- Cu-Sn ~ Cu-Zn

- Cu, Ni, Zn, Co, Mg, Pb, Sn and Ti alloys

*With UVTouch probe