Description

For 70 years, Krautkrämer ultrasonic transducers have been synonymous with quality.

Our core ability is to match ultrasonic probes to the inspection applications of today, both simple and complex. This skill lets allows us to design and manufacture fine-tuned quality probes that meet your customer-specific requirements. We build quality into every step we perform—from start to finish:

• Requirement analysis. At the very beginning of our discussions with you, we draw on our experience manufacturing more than 1 million probes—including 14,000 probe variations—to build quality into our requirement analysis process.

• Specifications. To help ensure quality results, each product in our one-stop-shop adheres to our exacting specifications.

• Simulation. Early in the process, we use industry leading simulation technology software to help us determine what needs to be done to meet application requirements. We also understand the boundaries of simulation and how that impacts the build.

• Feasibility studies. We support challenging applications by conducting feasibility studies in our labs, which are located worldwide. Send us your samples and we can determine the best inspection method and technology.

• Material selection and processing. We use the highest standards when sourcing our raw materials, and our in-house manufacturing is fully controlled to ISO standards. Our ceramics shop in Shannon, Ireland, creates piezocomposite ceramics, an in-house offering unique to our business.

• Prototyping. With a strong understanding of your needs, we offer prototyping to further validate that the solution works.

• Product validation. With an emphasis on repeatability and process stability, our exacting build-and-test procedures and specifications are followed for every single build, meaning every step includes a quality inspection/test to meet required criteria. What’s documented: Each probe has a unique serial number, and every validated manufacturing step is recorded before shipment. Finally, our database stores historical test data for every probe. We provide a certification of conformance, including probe waveform and frequency spectrum results with each probe.

• Manufacturing. With manufacturing available in both Europe and the USA, we can provide local variation and meet local norms. In fact, we can customize your transducer to meet your specific ultrasonic testing applications. Modifications can involve transducer case design, connector options, and element size and shape, including non-standard frequencies, sensitivity, bandwidth and focusing.

• Delivery. Our pledge is to provide you with exceptional product availability with our global distribution sites and customer care resources, to ensure that order status is communicated until your probe reaches your door.

• Support. We have expert resources available to help you with your ultrasonic inspection challenges including field application engineers and remote service technicians who can be reached through phone or email 24/7. Our probes are backed by a standard one year repair or replace warranty as a testament that we stand behind our products. Krautkrämer ultrasonic transducers from Inspection Technologies deliver consistent readings. Our quality goes beyond standard, our pricing is competitive, and our products are delivered when and where you need them.

Now that’s quality, every step of the way.

| Straight Beam Transducers – Single Element

|

Typically used for manual inspections, straight beam single element transducers are ideal for scanning parts with regular geometry and relatively smooth contact surfaces. This includes flat or curved surfaces where you need to identify flaws or a backwall parallel to the surface or detect with a beam normal to the surface. With improved near surface resolution, you can use these probes along with a couplant layer (typically gel, oil, or paste) when you need to penetrate a thick section of material.

Browse Now |

| Straight Beam Transducers – Dual Element

|

Straight beam dual element (TR) transducers are best for manually scanning thin sections of material when looking for flaws or backwalls parallel to or those which are detectable with a beam normal to the surface. With excellent near surface resolution and reduced noise caused by scattering, these probes transmit and receive elements separated by a crosstalk barrier. They can be contoured and coupled on curved and rough parts and surfaces and do require a couplant layer, typically a gel, oil or paste.

For European Customers: Probe models have side mounted Lemo 00 connectors, side mounted Microdot SEB..KF types For North American Customers: Probe models use fixed BNC cable (ADP) or side mounted MMD (FDU) Browse Now |

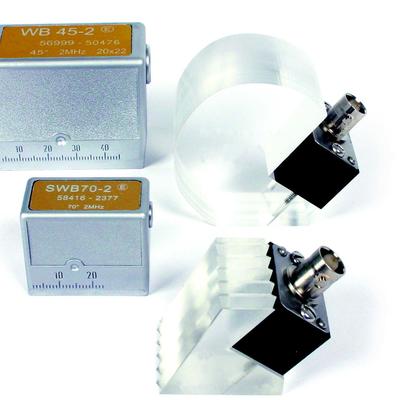

| Angle Beam Transducers

|

Angle beam probes are preferred for parts with inclined flaws, such as welds, and are sometimes used in mechanized or automated testing. They use refraction to transmit shear or longitudinal waves at a predetermined angle, while most standard transducers generate shear waves by mode conversion. Elements are mounted on integral or replaceable wedges, requiring a couplant layer, typically a gel, oil or paste.

Our angle beam probes are available in both single and dual element types, and in multiple sizes. Browse Now |